- Article Summary

-

Introduction

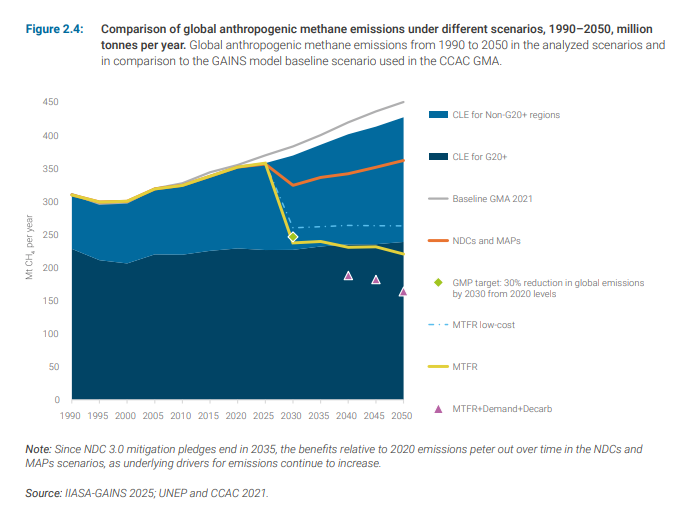

Methane is one of the most powerful climate forcing gases and the 2025 Global Methane Status Report confirms that global emissions continue to rise. At the halfway point of the Global Methane Pledge, operators face a period defined by higher expectations, stronger regulation and an increasing focus on verified emissions. Methane is responsible for a large share of near term warming and rapid reductions deliver measurable climate and public health benefits.

The report confirms that current inventories and national level greenhouse gas accounting methods underestimate real world emissions from oil and gas systems, coal operations and waste sites. This creates risk for operators who rely on generic emission factors because future regulatory systems require measurement based outputs rather than estimates.

The industry is entering a new era in which operators must be able to detect, quantify and verify methane at the facility level. This shift has direct implications for producers, midstream operators, LNG exporters and any company required to report or reduce methane emissions under emerging national and international rules.

The End of Estimates: What the Global Methane Status Report Reveals About Underreported Leaks

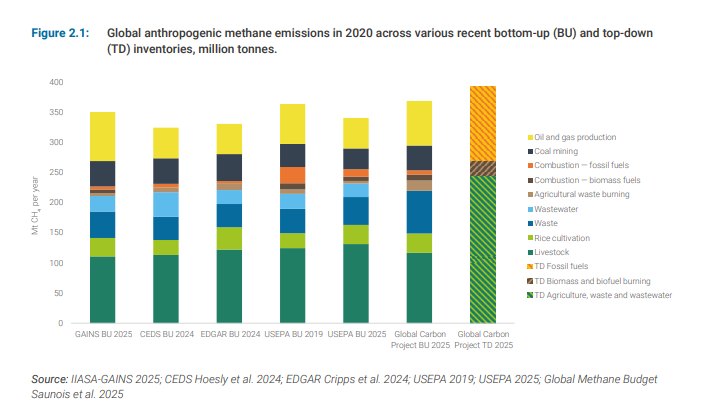

The Global Methane Status Report shows that measured emissions are often significantly higher than what traditional inventories suggest. Multiple studies highlight that onshore production regions release more methane than expected, while some offshore sources emit far less than reported values. Coal sector measurements also show that default factors may not capture the full picture for active mines or abandoned sites.

These findings confirm that emission factor based reporting does not align with actual facility level conditions. Many leaks and operational events are intermittent or equipment specific, which makes them invisible to static estimation approaches. As a result, operators relying on estimates face higher uncertainty in reporting and may also lack the data needed to target the most important sources.

A measurement based approach provides the detail needed for operational teams and compliance departments. High frequency leak detection, on site quantification and continuous monitoring at key points give operators real visibility into emissions and help identify where action is most effective.

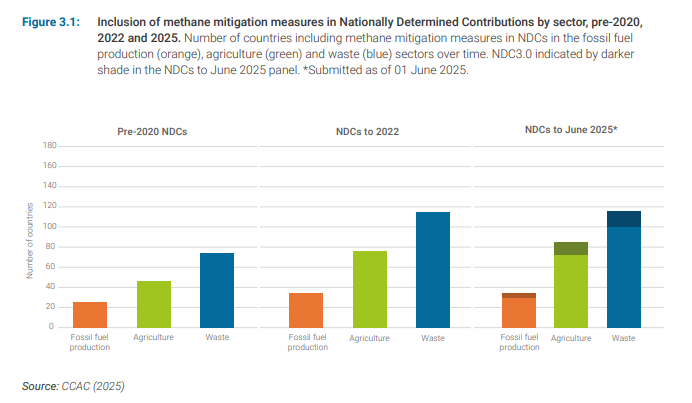

The Regulatory Shift Toward Direct Measurement

New policies in major markets now require operators to demonstrate that their methane reporting is based on real measurements. EPA requires instrument based leak detection and clear documentation of monitoring and repair schedules. The Inflation Reduction Act methane fee places financial weight on accurate quantification, which creates an incentive to track emissions with greater precision. OGMP 2.0 requires operators to reach the higher levels of the framework where real measurement data replaces default values. The European Union Methane Regulation requires verified emissions data for imports and places new obligations on producers that supply international markets.

These rules create a consistent message. Operators must transition from paper based LDAR programs and irregular inspection cycles to modern digital MRV (measurement, reporting and verification) systems that integrate detection, quantification, verification and reporting. Without direct measurement, reporting will fall short of regulatory expectations and commercial partners will question emissions intensity claims.

Ground Level Data: The Operational Methane Controls That Deliver Fast Reductions

The report highlights that over 80 percent of global methane mitigation potential comes from low cost actions at the facility level. These actions are real opportunities for operators because they reduce emissions without requiring major structural changes. The most impactful measures include frequent leak detection and repair, upgrading pneumatic devices, maintaining compressor seals, improving flare operations and replacing worn components.

These operational measures require reliable data. A modern MRV system designed for methane gives operators the ability to centralize inspections, store instrument based readings, quantify leaks and document repair activity. Digital platforms also support audit readiness by aligning data collection with EPA, OGMP and European Union requirements.

A measurement based program improves efficiency for field teams and gives leadership a clear view of emissions risk. When operators can track leak volume, repair time and equipment level trends, they can prioritize investments and reduce both emissions and operational losses.

Building a Measurement Based MRV Program: Practical Steps for Operators

A modern methane MRV program combines detection, quantification, verification and reporting in one integrated workflow. Operators can begin by increasing the frequency of LDAR inspections, deploying instrument based technology at priority sites and digitizing data collection. Adding continuous monitoring at high risk equipment helps capture intermittent events that may not appear during scheduled surveys.

Once data collection is consistent, operators can build emissions quantification models that meet regulatory expectations. Digital platforms simplify the transition by providing structured workflows, automated recordkeeping and reporting templates aligned with EPA and OGMP standards. These systems also reduce error rates and improve transparency across operations.

The business case is strong. Better emissions intelligence reduces regulatory exposure, lowers methane fee liability, strengthens LNG contract positions and improves ESG performance. Companies that adopt measurement based MRV early gain an advantage because they can demonstrate credible emissions performance to regulators, investors and commercial partners.

Conclusion

The methane measurement era has arrived and operators must be ready for a future defined by precise data rather than estimates. Accurate detection and quantification are essential for compliance and for maintaining access to global markets. Measurement based MRV supports operational efficiency and strengthens climate performance. Companies that invest now will be positioned to lead the next decade of low methane energy.

Why Work with ASUENE Inc.?

ASUENE is a key player in carbon accounting, offering a comprehensive platform that measures, reduces, and reports emissions. The company serves over 10,000 clients worldwide with an all-in-one solution that integrates GHG accounting, ESG supply chain management, a Carbon Credit exchange platform, and third-party verification.

ASUENE supports companies in achieving net-zero goals through advanced technology, consulting services, and an extensive network.