- Article Summary

-

Overview of Category 5: Waste Generated in Operations

Scope 3 Category 5 accounts for emissions from the treatment and disposal of waste that is generated by a company’s own operational activities, but handled by third parties. This includes emissions from landfilling, incineration, recycling, composting, and wastewater treatment.

Although often smaller in scale compared to other Scope 3 categories, this category holds increasing importance due to its visibility in circular economy strategies, waste legislation, and the rising carbon intensity of certain waste streams (e.g. plastics, food waste).

For companies in manufacturing, food services, retail, and logistics, effective waste management is both a climate opportunity and a compliance necessity.

Boundary and Scope Definition

Included in this category:

- Solid waste sent off-site (e.g. packaging waste, production scraps)

- Hazardous waste disposal by third parties

- Wastewater treatment by external providers

Excluded from this category:

- Waste from sold products (Category 12)

- On-site waste incineration (Scope 1)

Relevant frameworks:

- EU Waste Framework Directive (updated 2025): Pushes for lifecycle accounting of corporate waste

- ESRS E5: Requires disclosure of waste intensity and treatment method breakdown

Calculation Methodologies

Emissions from waste can be calculated using:

- Waste-Type and Treatment Method Approach: Multiply quantities of each waste type by treatment-specific emission factors (e.g. landfill, incineration, recycling)

- Facility-Specific Data: Use data provided by waste contractors or local authorities (if available)

- Spend-Based Method: For non-material waste streams, use cost data with average emissions per dollar spent (least accurate)

Use treatment-specific emission factors based on:

- Waste type (organic, plastic, metal, etc.)

- Treatment method (landfill, composting, etc.)

- Regional variations in energy recovery or methane capture

Data Collection Strategies

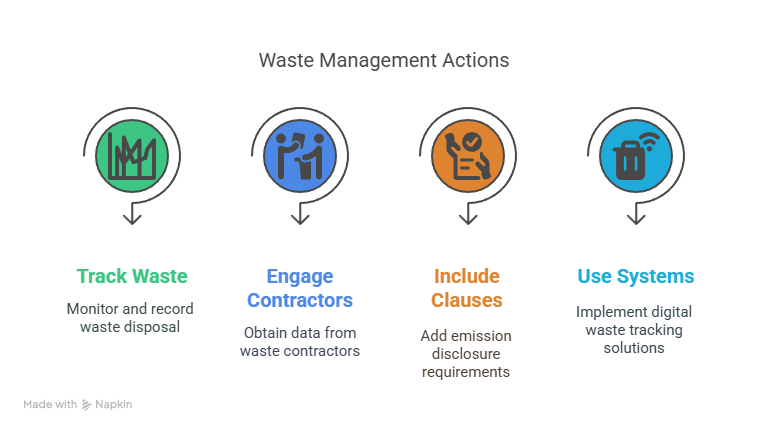

To build a complete picture of operational waste emissions, companies should:

- Track Waste Volumes: Log all waste movements, categorized by type and destination

- Engage Waste Contractors: Request verified data on treatment methods and recovery rates

- Include Clauses in Waste Service Agreements: Require disclosure of emissions data and treatment breakdown

- Use Digital Waste Tracking Systems: Implement systems that integrate with facility reporting tools

The updated EU regulations may mandate third-party verification of waste data by 2026.

Emission Reduction Approaches

Reducing Category 5 emissions involves both upstream waste prevention and downstream treatment optimization:

- Reduce and Redesign: Minimize waste through lean manufacturing and packaging design

- Source Separation: Enable high-quality recycling by sorting at the point of generation

- Switch Treatment Methods: Shift from landfill to composting, anaerobic digestion, or recycling

- Use Circular Contracts: Work with recyclers and recovery facilities with closed-loop systems

- Employee Training: Embed waste awareness in operational behavior

These actions not only reduce emissions but may lower operational costs and improve ESG ratings.

Case Studies: Waste Management Leadership in Scope 3

H&M Group

H&M has implemented garment recycling and sorting infrastructure across its logistics and store network, reducing landfill waste and Scope 3 emissions from incineration. (H&M Sustainability Reporting)

Danone

Danone tracks operational waste across its factories, with over 80% sent for recovery or recycling. It includes waste emissions in its GHG inventory and aligns targets with circularity goals. (Danone Integrated Annual Report)

L’Oréal

L’Oréal integrates waste KPIs into operational performance and reduced industrial waste per finished product by 35% between 2005 and 2022. It uses zero-landfill strategies across manufacturing sites. (L’Oréal Sustainability Commitments)

These companies show how strategic waste management can support Scope 3 reduction targets while advancing broader environmental goals.

Why Work with ASUENE Inc.?

Asuene is a key player in carbon accounting, offering a comprehensive platform that measures, reduces, and reports emissions, including Scope 1-3, with expertise in decarbonization. Asuene serves over 10,000 clients worldwide, providing an all-in-one solution that integrates GHG accounting, ESG supply chain management, a Carbon Credit exchange platform, and third-party verification.

ASUENE supports companies in achieving net-zero goals through advanced technology, consulting services, and an extensive network.